Laser Cutting 101

Since the Early Stone Age, humans have been trying to make the act of making things a little easier on ourselves. And it’s safe to say that we’ve come a long way since the early hand axes and tools of 1.76 million years ago. Now, luckily for us, we can leverage literal laser beams and advanced computing technologies to make cool things faster and bigger than ever before.

What is a laser cutter?

A laser cutter is a fabrication tool that uses powerful laser beams to melt, burn, or vaporize materials. It is generally agreed that it was invented by Kumar Patel who developed the first CO2 laser in 1963.

A laser cutter’s beam usually has a diameter between 0.1 and 0.3 mm and a power of between 1 to 3 kW. The power is adjusted depending on the type of material being cut and its thickness.

Laser cutters have a couple of core components that are similar across types, and they are all every bit as cool as their names would suggest:

The Laser Resonator

The laser resonator is an airtight glass tube with two mirrors that face each other. The tube is filled with CO2 and other gases. That cocktail of gases is activated by diodes or electric discharges that then emits energy in the form of light. It’s where our laser beam emanates from.

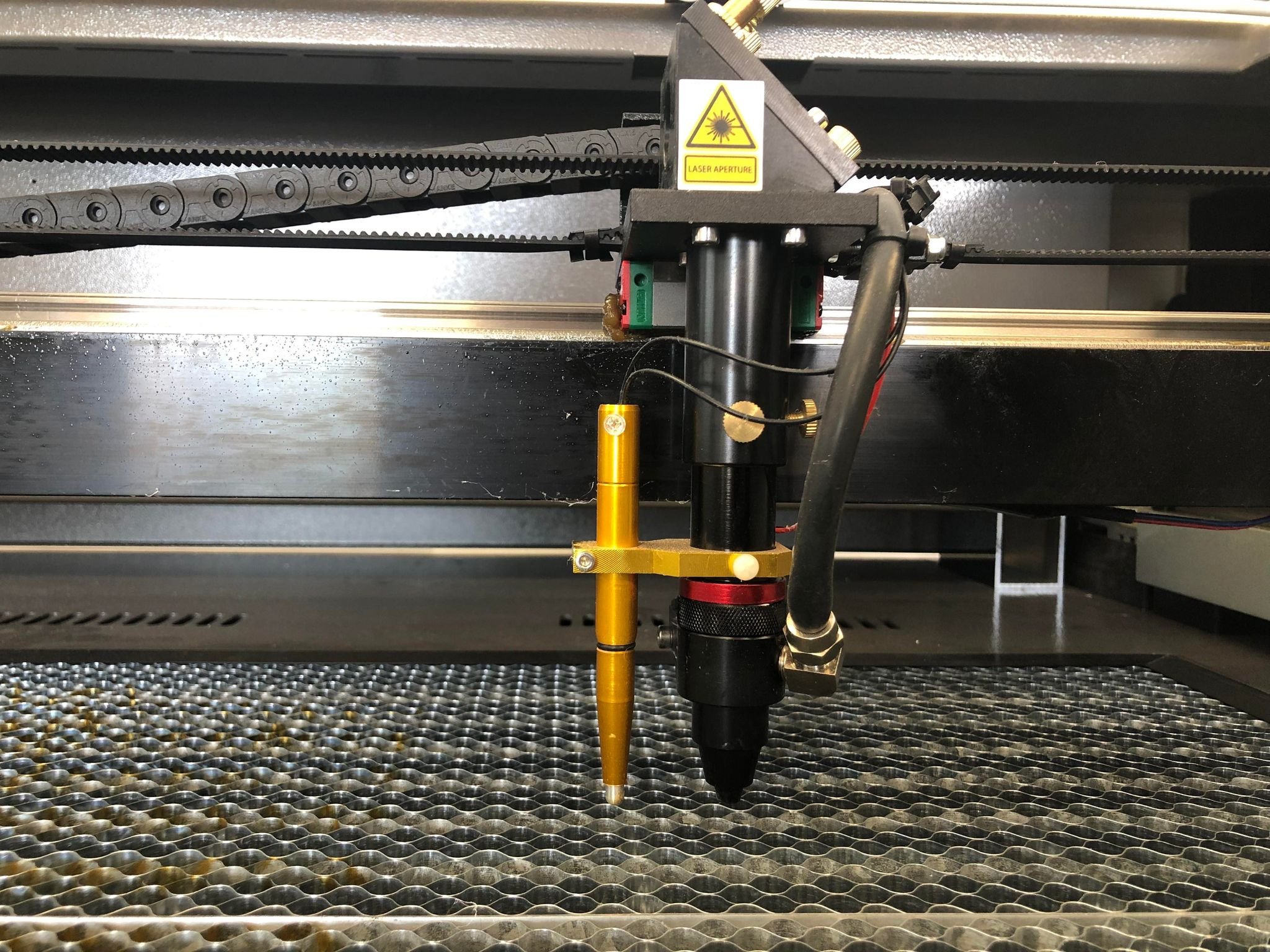

The Cutting Head

The laser beam gets bounced around the machine by a series of mirrors that are positioned strategically to direct it to the cutting head. Once the light hits the cutting head, it is directed down through a curved lens where it’s magnified and focused onto a single point. This beam of powerful light passes through a nozzle before hitting the plate with compressed gas like nitrogen or oxygen in the mix. If you’re cutting something like aluminum or stainless steel, the laser beam will melt the material before the highly pressurized nitrogen blows molten metal out of the kerf.

Normally the cutting head is attached to a mechanical system that is driven by a belt, which allows it to make really precise movements.

What is the laser cutting process?

Laser cutting is a fabrication process that uses a thin, focused beam of intense light to cut and etch materials into custom shapes, designs and patterns. It’s ideal for wood, glass, paper, metal, and gemstones.

Laser cutters are also capable of producing intricate parts without needing a custom designed tool. It’s a non-contact, thermal-based fabrication process and there are three major varieties:

Flame/Reactive Rutting

In this variety of laser cutting, the assist gas is oxygen, which is blown at a high pressure. The heated material reacts with the oxygen and begins to burn and oxidize. This thermal reaction expels more energy and helps the laser beam.

Fusion Cutting AKA the Old Melt & Blow

An inert gas–usually nitrogen–blows molten material out of the kerf, significantly reducing the power that’s required to make laser magic happen. The material is heated up until it reaches its melting point, then the gas blows it out.

Remote Cutting

A high-intensity laser beam evaporates the material partially, making it so thin sheets can be cut without the need of assist gas.

What’s the difference between laser cutting and engraving?

By changing the intensity of the laser beam and the speed of its movements, laser cutting machines can also engrave and mark wood. The laser can either be used to remove surface material to engrave a design, or mark material by altering the appearance at a surface level.

What are the pros and cons of laser cutting

There are a lot of advantages to laser cutting. Some of the reasons you might use laser cutting instead of something like CNC milling are:

Laser cutting is highly precise and accurate

Laser cutters have a high production speed

Lasers are more affordable than CNC machines of a similar caliber

Laser cutting has a wide range of material compatibility

There’s no risk of contamination with laser cutting (it’s contactless)

Laser cutting allows for narrower kerf widths

No process is perfect, and there are a few cons associated with laser cutting, such as:

High energy consumption

Risk of toxic emissions release from plastics (IE: why we don’t cut PVC)

Thicker materials can be difficult to fully cut

Burning at the edges can occur (for some people this is a pro because the finish looks cool)

What is laser cutting good for?

Laser cutters are fun, fast and handy tools for fabrication and prototyping. They allow designers to quickly and affordably iterate on designs before producing at a large scale. Laser cutting is a great technique for artists and makers bringing their digital designs into the world.

What are the limitations of a laser cutter

Laser cutting is not ideal for metals like aluminum and copper alloys because they have excellent heat-conductive and light-reflective properties, meaning they need powerful lasers.

What are the different types of laser cutters?

There are a few different types of laser cutters that come down to the different types of lasers in the actual machines. Different lasers can cut different material thicknesses. Generally, a high-powered laser will be better for professional applications where large sections of plastic or metal need to be cut. Conversely, other lasers are effective with materials like acrylic and wood.

CO2 Laser Cutters

With CO2 lasers, the cutting is done using electrically-stimulated CO2. CO2 lasers have enough energy to pierce through thicker material compared to fiber lasers with the same power because they emit a 10.6mm wavelength.

CO2 lasers also give a smooth finish when used to cut thicker materials. These are the most common types of laser cutters because they’re efficient and can cut and raster lots of materials including glass, acrylics, some foams, leather, paper based products, wood and some plastics. The laser cutter here at Larrikin, lovingly named Lara, is a CO2 laser.

Check out our material guide for more info >

Crystal Laser Cutters

Crystal laser cutters can cut through strong, thick materials because they have smaller wavelengths and higher intensity, but they tend to run through parts quickly because of the high power.

They’re good for plastics, metals and some ceramics.

Fiber Laser Cutters

Fiber laser cutters cut using fiberglass. The lasers originate from a ‘seed laser’ then are amplified by special fibers. Fiber lasers are in the same category as disk lasers, and belong to a class called ‘solid-state lasers’. Compared to a CO2 laser, fiber lasers don’t have moving parts, are 2-3 times more energy efficient, and are capable of cutting reflective materials without worrying about back reflections. These layers work with both metals and nonmetals.

What type of laser is most popular?

Out of the three, CO2 lasers like ours are the most common. They are used primarily for cutting non-metal materials, and even though there are some who can cut through metals, they are still better suited for woods, leathers, rubbers, etc.

If you’re ready to start using laser beams, send us your files today!